What You Need to Know

Chris Irwin achieved amazing organizational success in applying Lean principles in his workplace, eliminating a longstanding backlog of over 4,000 files in just two months.

Telfer Executive Programs offers the Lean & Agile Leadership Program for aspiring Lean champions.

Can you obtain skills to supercharge how quickly your department completes its work in only three days of learning? Chris Irwin did just that by participating in the Telfer Executive Programs Lean Yellow Belt program.

The Lean Yellow Belt program is designed for participants to learn the basics of Lean principles and how to improve a simple process at work. Chris, however, had ambitious goals for his program learning. Instead of improving a simple process, he applied his learning to a prominent, complex process at the Ministry of Transportation of Ontario. He and his team reduced the waiting time for a Commercial Vehicle Renewal from 94 days to just five days, eliminating a longstanding backlog of over 4,000 files in just two months. His department accomplished this without adding new technology or increasing the number of people on their team. That team was so energized by the experience that they kept improving the process on their own for years to come. Chris went on to replicate his success by applying Lean principles across the Ontario Public Service in other departments.

We sat down with Chris to learn more about his experience in the program and his success in transforming his departments’ processes.

Q: What interested you in the Telfer Lean Yellow Belt program?

Chris: I was the Organizational Change Management Manager on a major legacy IT system replacement. I wanted my team to be helpful to both the business area we were supporting and the system developers who were building the digital requirements. My Assistant Deputy Minister, in an almost off-hand remark, suggested I have a look at Toyota and how they work. At this point I’d never heard of Lean, and only knew Toyota as a kind of car.

I started to read about the story of Lean, starting with Toyota, and how it had spread from manufacturing environments, to service environments and from the private sector to the public sector. I became fascinated with Lean applied in the public sector - and started immediately seeing how beneficial it could be to my work, and more broadly to the Ontario Public Service.

I chose Telfer Executive Programs because it was one of the few schools focused on Lean application in the public sector. I had discovered a presentation from a Conference Board of Canada conference where the speaker, Craig Szelestowski, eloquently pulled together Lean in a public sector context. I contacted him: he happened to be the facilitator of the Telfer Lean Yellow Belt program and suggested that I attend the program. I got the green light from my boss and signed up.

It’s an understatement to say it was the most impactful training of my life. I leveraged it to become a key champion for Lean in the Ontario Public Service and went on to co-found the Province’s Lean and Continuous Improvement Office and became its first Director. I still apply the learning from that program to this day. I went on to train thousands of public servants in Lean and worked with teams to save thousands of hours and millions of dollars.

Q: How was your experience in the program?

Chris: The program was excellent: a perfect combination of learning and hands-on application. I walked away with comprehensive materials and the tools to apply Lean in my workplace right away. The facilitators were professional and incredibly knowledgeable, but even more impressive was their passion for the practice of Lean and their generosity in sharing their stories and expertise. Over the course of a few days, they became invested in my success - they wanted me to take this knowledge back and use it to improve my workplace. They were setting me up to become a Lean champion.

Q: Can you describe how you applied the learning to get rid of the backlog and streamline the process so dramatically? What problems did you solve?

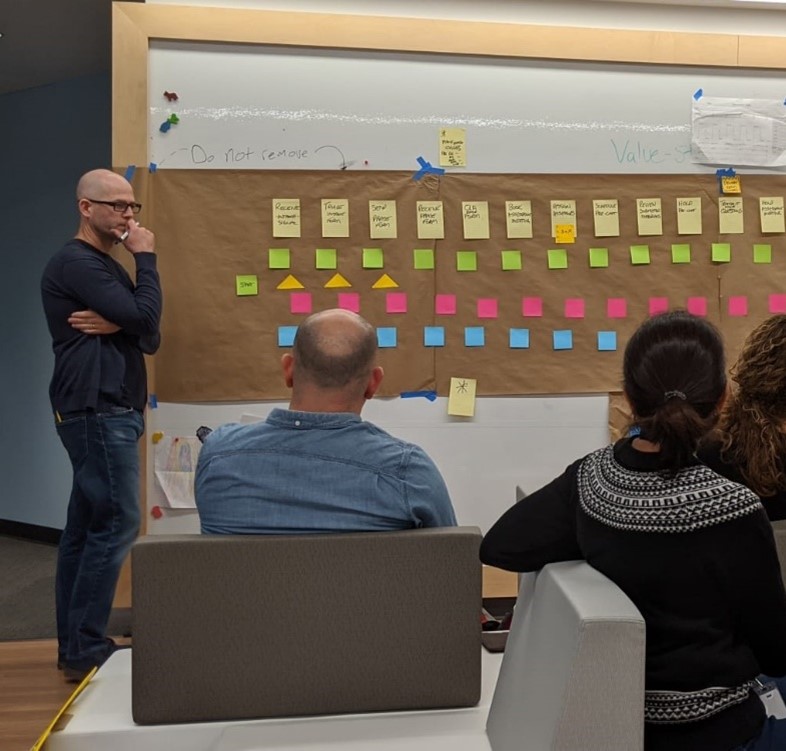

Chris: The training and materials I gained from the program allowed me to make the case to my boss to try out a Lean project within the program area I had been working with as a change leader. I trained the team who reported to me, and then with the support of leadership, I booked the biggest boardroom I could find. I took ten staff off the production line for a one-week sprint and went through the DMAIC (Define, Measure, Analyze, Improve, and Control) methodology from Lean Yellow Belt. On Friday afternoon, the Director came to see the results. The team and I walked them through the current state value stream map which showed 94 days to process a vehicle renewal - and then a future state. The Director looked at us and said, “So, you can get this from 94 days down to one day?” We said we thought we could. The Director said, “Okay, let’s start on Monday.” Within two weeks, we were able to turn around vehicle renewals in less than two weeks and the systemic backlog was eliminated in two months.

Q: What did you learn from the program about the human side of change?

Chris: Part of what attracted me to Lean was its focus on people - this was something that was reinforced in the program. I already understood that the public servants I worked with were hard-working and dedicated. But I started to understand that it was the systems and processes around them that were getting in the way. “That’s just the way we do things here,” was a refrain I heard often in my job. I was always resistant to and questioning of that refrain - but it wasn’t until Lean Yellow Belt that I had the tools to provide an alternative.

Q: What did you learn about leadership in this transformation?

Chris: A few things:

You can only go as high as your leadership allows – start with leaders and help them understand how they can use their influence to get their processes to go 80% faster with better quality and engaged people. They have very specific opportunities to make improvement happen, and often don’t know without some mentoring what their role could or should be.

Get leaders to see the work as a system. Different leaders own different functions or islands, but processes must flow across these islands. Usually, they can only see their own island and thus they optimize that, but that happens at the expense of the flow across all of the islands. Once leaders can see the whole system, they stop focusing on optimizing only their own islands, and collaborate with other leaders to make the work flow across all islands, delivering much faster and better results.

Only leaders can create and sustain the psychological safety needed to make finding problems praise-worthy instead of blame-worthy. If we’re afraid to identify and discuss problems, then we’ll likely never solve them. Building psychological safety makes everything else go faster and better.

Q: What has happened in your Ministry in the intervening years since you first cleared the backlog? Have there been other innovations or improvements?

Chris: We went on to apply Lean to a dozen services in the area. There were setbacks for sure, and many lessons learned. It all went into improving my practice of Lean, as well as my leadership of Lean transformation teams. We started to spread Lean to other program areas and it’s still part of the Ministry of Transportation to this day, almost 10 years later.

Q: What were the next steps that you took in your career after this transformation?

Chris: I continued to apply Lean thinking to my work. I sought out more Lean projects and I went on to get my Black Belt. I became a thought leader in applying Lean in the public sector. I began building Lean teams, then internal consulting units. I was tapped to help found the Ontario Public Service’s first enterprise-wide Lean and continuous improvement office and became its first Director.

In the years since I was a participant at Telfer Executive Programs, I’ve been involved with hundreds of Lean projects, which have saved countless hours of wasted time and millions of dollars. I plan to keep at it.

Q: What advice would you give to someone who is looking to make a process change in their organization?

Chris: Here are some of my tips & tricks:

Study a process, really learn to see it, and then teach leaders and others to see it. Most people are so immersed in their processes and so starved for time that problems have blended into the woodwork and become difficult to see.

Start with thinking about the problem you are trying to solve. Resist the urge to jump to solution thinking early by trying to understand causes first. I’ve seen countless situations where the hasty solution either didn’t pan out or made the situation worse.

Distinguish work you should be doing versus work you could avoid. This is initially very hard for teams because all work starts to look the same over time.

Get data and use it in every aspect of your work. I tell my teams when they present a problem statement or a recommendation to a client to “wash it with data,” ensuring it is grounded in evidence.

Get obsessive about implementation. Many Lean projects assume the finish line is the moment improvement recommendations have been made. Start to think of recommendations as the starting line – changes still must be implemented, and that is where results are achieved and a culture of continuous improvement is created.

The Telfer Lean Yellow Belt program has been discontinued, but Telfer Executive Programs has a suite of offerings for aspiring Lean champions. Register for the Lean & Agile Leadership Program today to begin transforming your department!